Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

CGeotechnical Influence of Waste Materials in Road Construction

Authors: G. Pravalika, K. Koushik Reddy, P. Sanjeev, S. Saketh, Mrs. G. Kalyani

DOI Link: https://doi.org/10.22214/ijraset.2024.60218

Certificate: View Certificate

Abstract

A shortage of construction materials and the subsequent rise in their rates has lead to an increase in the cost of road construction in many folds. The shortage of construction material is across the country due to a ban on mining and scarcity of open land for borrows areas. On the other hand, construction of flexible pavement demands enormous quantities of raw materials including soils. In the coming decades the design, construction and maintenance of roads will face a range of new challenges and as such will require a number of new approaches. Such challenges will result from a growing number of interconnected environmental, social, and economic factors, which are set to apply significant pressure on the future of roads. Natural materials are exhaustible in nature. Hence, their quantity is declining gradually day by day. Concerned about this, highway engineers and scientists have started looking for alternative materials for highway construction, and waste product is one such category. If these materials can be suitably utilized in highway construction, the pollution and disposal problems may be partly reduced. Huge amount of construction materials are required to meet the demands of the increasing road network in India

Introduction

I. INTRODUCTION

Tremendous increase in road infrastructure has been achieved during the last centuries. Road network in India increases in manifolds under various development schemes like National Highways Development Programme (NHDP), State Highways Improvement Programmes (SHIPS), Pradhan Mantri Gram Sadak Yojana (PMGSY), Bharat Nirman etc. In order to cater the heavy traffic conditions on the main corridors, a high quality pavement structure is required. The road network has been quantitatively significant under the Golden Quadrilateral project and the North-South and East-West corridors project of National Highways Authority of India (NHAI). Generation of waste increases with the growth of population and remains undecomposed in the environment for several years. Waste disposal crisis arise due to these nondecaying waste materials along with growing population. The best solution to overcome this is its utilization in productive manner. Enormous quantities of domestic, industrial, agricultural and mining waste are generated annually in India. Factors that have reduced the implication of waste management are lack of financial resources, institutional weaknesses, improper choice of technology and community indifference towards waste. Serious environmental and public health problems have been resulted due to uncontrolled dumping of waste on the outskirts of towns and cities. Industrialization in India has rapidly increased the waste generation. Hence it is a challenging job for the authorities to utilize this waste efficiently and ensure safe disposal of these waste. Implementing new technologies to recover resources from waste management is the only optimal solution for this

II. MATERIALS USED

A. Coconut Husk Ash

Coconut husk ash, a byproduct of the coconut industry, has gained attention in recent years due to its diverse applications across various fields. From agriculture to construction, this seemingly humble residue holds immense potential. This essay delves into the properties, uses, and benefits of coconut husk ash, shedding light on its importance in sustainable development.

B. Properties of Coconut Husk Ash

Coconut husk ash is primarily composed of silica, potassium, calcium, and magnesium oxides, along with traces of other elements. Its chemical composition renders it highly alkaline, with a pH ranging from 9 to 12.

The high silica content gives it excellent pozzolanic properties, making it suitable for use in concrete production. Additionally, its porous nature enhances water retention, making it beneficial for soil amendment in agriculture.

C. Applications in Construction

In the construction industry, coconut husk ash finds application as a supplementary cementitious material. When combined with Portland cement, it enhances the strength and durability of concrete structures. Its pozzolanic properties react with calcium hydroxide released during cement hydration, forming additional binding compounds that reduce porosity and increase the density of concrete. This results in improved resistance to corrosion, sulfate attack, and alkali-silica reaction, thereby prolonging the lifespan of buildings and infrastructure.

D. Environmental Benefits

The utilization of coconut husk ash offers significant environmental benefits. By repurposing agricultural waste, it reduces the burden on landfills and minimizes environmental pollution. Furthermore, its use in agriculture reduces the reliance on synthetic fertilizers, thereby decreasing chemical runoff and preserving water quality. In construction, it contributes to the reduction of carbon emissions associated with cement production, making it a more sustainable alternative.

E. Challenges and Considerations

Despite its numerous advantages, the widespread adoption of coconut husk ash faces some challenges. Variability in ash composition, depending on factors such as coconut variety and processing methods, can affect its performance in different applications. Moreover, proper quality control measures are necessary to ensure its safe and effective utilization, particularly in construction, where structural integrity is paramount. Coconut husk ash, with its versatile properties and eco-friendly attributes, presents a valuable resource for sustainable development. Whether enhancing soil fertility in agriculture or improving the strength of concrete in construction, its applications are diverse and impactful. As efforts to promote circular economy practices and reduce environmental footprint intensify, the utilization of coconut husk ash emerges as a promising solution, embodying the principles of resource efficiency and environmental stewardship. In essence, coconut husk ash embodies the adage of turning waste into wealth, demonstrating that even the most seemingly insignificant byproducts can hold immense value when harnessed innovatively and sustainably.

III. BLACK COTTON SOIL:

Black cotton soil, also known as black clay soil or regur soil, is a unique type of soil found in several regions around the world, including parts of India, Africa, Australia, and the United States. Characterized by its dark color and high clay content, black cotton soil has intrigued scientists, farmers, and engineers for centuries due to its distinct properties and diverse implications. This essay explores the composition, characteristics, challenges, and agricultural significance of black cotton soil.

A. Composition and Characteristics

Black cotton soil derives its name from its dark color, which results from the high organic matter content and iron oxide concentration. However, its defining feature lies in its clayey texture, composed predominantly of montmorillonite, a type of swelling clay mineral. This composition imparts unique properties to black cotton soil, including high plasticity when wet and significant shrinkage and cracking upon drying. Additionally, its high moisture retention capacity makes it prone to waterlogging during the rainy season and severe cracking during dry spells. Despite its challenging nature, black cotton soil plays a crucial role in agriculture. In regions where it is predominant, such as parts of India's Deccan Plateau, it supports diverse crops, including cotton, soybeans, pigeon peas, and sorghum. Its fertility stems from the presence of essential nutrients and minerals, such as calcium, magnesium, and potassium, which are released gradually as organic matter decomposes. However, managing black cotton soil poses significant challenges due to its tendency to become hard and compacted when dry, hindering root penetration and water infiltration.

B. Challenges and Mitigation Strategies

Farmers and agricultural experts face several challenges when cultivating crops in black cotton soil. The soil's high clay content makes it prone to compaction, limiting aeration and root development. Furthermore, its propensity for waterlogging can lead to reduced crop yields and increased susceptibility to diseases. To mitigate these challenges, farmers employ various techniques, including deep plowing to improve soil structure, contour plowing to prevent erosion, and the use of organic amendments to enhance soil fertility and water retention.

C. Engineering Implications

Beyond agriculture, black cotton soil presents challenges and opportunities in civil engineering and construction. Its expansive nature, characterized by significant volume changes in response to moisture variations, poses risks to infrastructure, such as roads, buildings, and pipelines.

Engineers must account for these soil mechanics phenomena when designing foundations and structures to prevent damage from swelling and shrinkage. Moreover, innovative techniques, such as soil stabilization with lime or cement, can improve the engineering properties of black cotton soil, making it suitable for construction project.

IV. OTHER MATERIAL WHICH CAN BE USED IN STABILIZING:

Stabilizing black cotton soil for construction presents a significant engineering challenge due to its expansive nature and sensitivity to moisture changes. However, several materials and techniques can be employed to enhance its engineering properties and ensure the stability of structures built upon it. Here are some commonly used materials for stabilizing black cotton soil:

A. Lime

Lime is a widely used stabilizing agent for black cotton soil. When mixed with the soil, lime reacts with clay minerals, causing flocculation and improving soil structure. This process reduces plasticity, increases soil strength, and enhances load-bearing capacity. Lime stabilization also reduces soil swelling and shrinkage, making it less susceptible to volume changes due to moisture variations.

B. Cement

Cement stabilization involves mixing cementitious materials, such as Portland cement, with black cotton soil to improve its engineering properties. Cement reacts with soil particles, forming cementitious bonds that increase cohesion and shear strength. Cement stabilization is particularly effective in reducing soil plasticity, increasing bearing capacity, and minimizing settlement. However, it requires careful control of mixing proportions and curing conditions to achieve optimal results.

C. Fly Ash

Fly ash, a byproduct of coal combustion in power plants, can be used as a supplementary stabilizing agent for black cotton soil. When mixed with soil, fly ash reacts with lime and moisture, forming cementitious compounds that bind soil particles together. This process enhances soil strength, reduces plasticity, and improves durability. Fly ash stabilization is cost-effective and environmentally friendly, as it utilizes a waste material while reducing the demand for natural resources.

D. Bitumen

Bitumen stabilization involves mixing bituminous materials with black cotton soil to enhance its engineering properties. Bitumen coats soil particles, providing waterproofing and increasing resistance to moisture-induced volume changes. Bitumen stabilization is commonly used in road construction, where it improves soil strength, reduces pavement deformation, and enhances durability. However, it requires careful temperature control during mixing and compaction to achieve effective bonding between soil and bitumen.

E. Polymer Additives

Polymer additives, such as polymeric emulsions or fibers, can be incorporated into black cotton soil to enhance its stabilization. Polymer additives improve soil cohesion, reduce plasticity, and increase tensile strength. They also improve resistance to erosion, cracking, and weathering. Polymer stabilization is particularly beneficial in areas with high traffic loads or where soil stabilization needs to withstand dynamic loads.

F. Chemical Stabilizers

Various chemical stabilizers, such as sodium chloride (salt), potassium chloride, or calcium chloride, can be used to improve the engineering properties of black cotton soil. These chemical stabilizers enhance soil compaction, reduce swelling, and increase load-bearing capacity. However, their long-term effectiveness may depend on environmental conditions and soil composition.

G. Geosynthetics

Geosynthetic materials, such as geotextiles, geogrids, and geomembranes, can be used in combination with traditional stabilizing agents to reinforce black cotton soil. Geosynthetics improve soil stability, prevent erosion, and enhance drainage. They can also provide reinforcement in slope stabilization, retaining walls, and embankments, reducing the risk of soil failure and increasing overall structural integrity.

When selecting a stabilizing material for black cotton soil, factors such as soil composition, project requirements, environmental conditions, and cost-effectiveness should be considered. Additionally, proper testing, design, and construction practices are essential to ensure the successful stabilization of black cotton soil for construction applications.

Conclusion

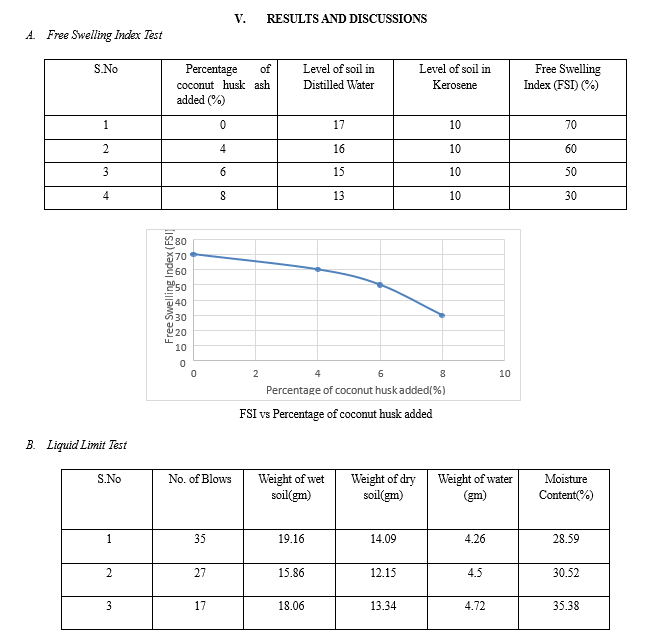

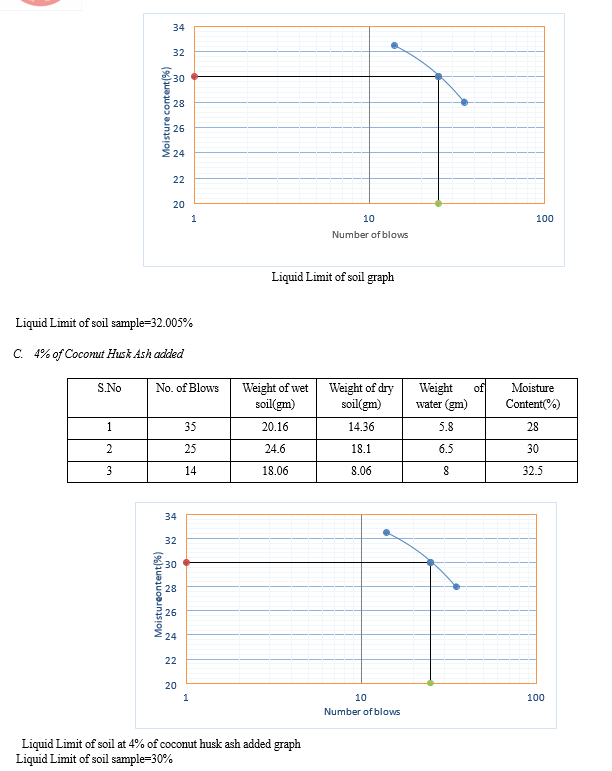

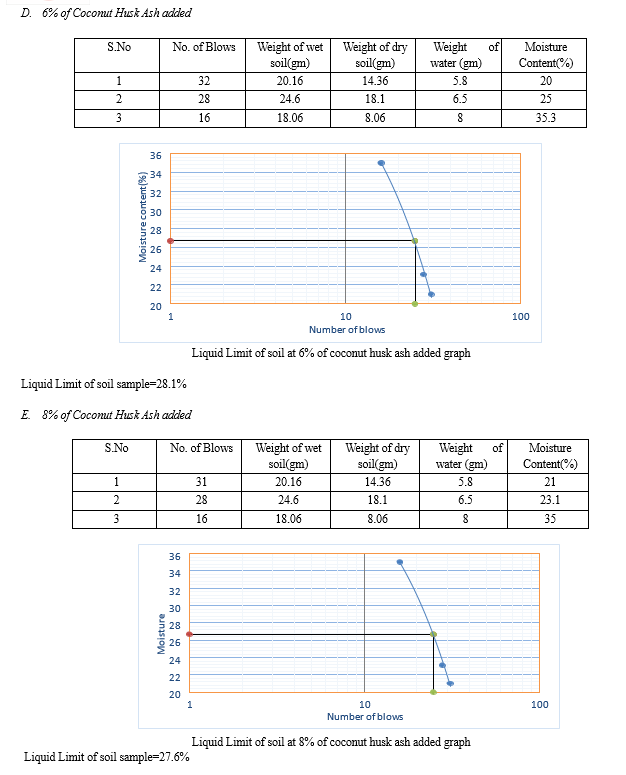

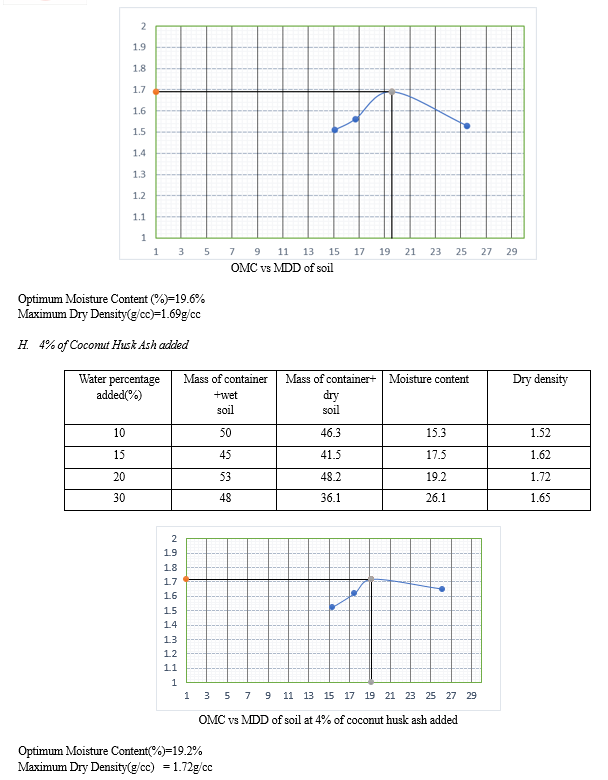

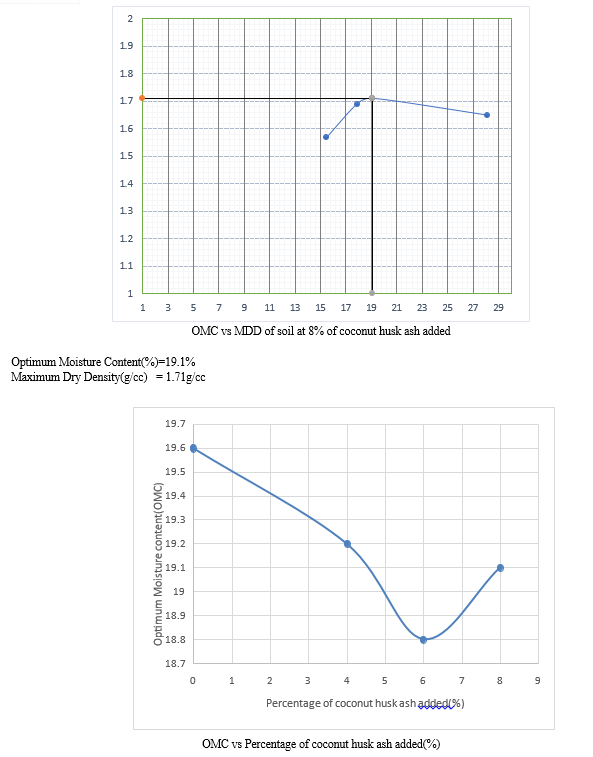

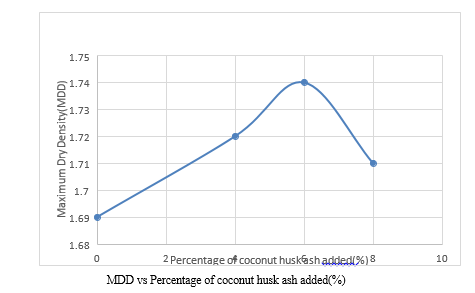

The present experimental study was carried out to find out the geotechnical properties of soil by stabilizing the clayey soil by using coconut husk ash. Use of coconut husk ash as a stabilizer for improving soil characteristics is an economical and effective solution . The following conclusions have been drawn based on laboratory investigations carried out in this study. In the first case, the property of natural soil determines the free swelling index as 70%. After adding 4%, 6% and 8% of coconut husk ash added, the free swelling index of soil decreased to 60%,50% and 30% respectively. It decreases the swelling index of the soil and hence increase in strength properties. The liquid limit and plastic limit of natural soil found to be 32.005% and 20.94% respectively. After adding coconut husk ash in natural soil in the different percentage that is 4%, 6% and 8% .It has been observed that the liquid limit value decreased to 28.1% with increasing percentage of coconut husk ash i.e. 6% and plastic limit value decreased to 18.6%. The optimum moisture contains in natural soil is 19.6% and maximum dry density is 1.69.And after adding the percentages of coconut husk ash the optimum moisture content(OMC) is decreased to 18.8% and maximum dry density(MDD) has increased to 1.74 at 6% of coconut husk ash. Hence, it was therefore concluded that coconut husk ash can effectively stabilize black cotton soil for road works.

References

[1] Ramadhansyah Putra Jaya” A Review of Utilization of Coconut Shell and Coconut Fiber in Road Construction” October 2015 Jurnal Teknologi . [2] Olugbenga Amu,“Potentials of Coconut Shell and Husk Ash on the Geotechnical Properties of Lateritic Soil for Road Works” April 2011 International Journal of Engineering and Technology. [3] Simeon Odunfa ,“coconut shell and fibre ashes for lateritic stabilization: index and bearing capacity properties” February 2024 ,Federal University of Agriculture, Abeokuta, Ogun State, Nigeria. [4] Iwona Chmielewska and Wojciech Gosk ” Sustainable soil stabilization: the use of waste materials to improve the engineering properties of soft soils” (2022), In?ynieria Bezpiecze?stwa Obiektów Antropogenicznych [5] Bindu C.S “Influence of Waste Materials on Flexible Pavement Construction” September 2015, Indian journal of applied research [6] Hussein Jalal Aswad Hassan, Jabar Rasul and Maleaha Samin” Effects of Plastic Waste Materials on Geotechnical Properties of Clayey Soil” 30 November 2021, Transportation Infrastructure Geotechnology (2021) [7] Ronaldo L. S. Izzo, Eclesielter B. Moreira and Jair A. Baldovino” Transforming Construction and Demolition Waste into Soft-Soil Treatment for Paving Design” 8 April 2020, Geotech Geol Eng [8] Nik Normunira Mat Hassan,Yasmin Yuriz and Tuan Noor Hasanah Tuan Ismail,” An Overview of Waste Materials for Sustainable Road Construction” International journal of sustainable construction engineering and technology vol. 11 no. 1 (2020) pp.215-229 [9] Brendan C. O’Kelly,Amin Soltani” Effects of Plastic Waste Materials on Geotechnical Properties of Clayey Soil”(2021) Transportation Infrastructure Geotechnology. [10] Zuzana Dimitrovová, Konrad Malicki and Jaros?aw Górszczyk “Recycled Polyester Geosynthetic Influence on Improvement of Road and Railway Subgrade Bearing Capacity— Laboratory Investigations” Materials 2021. [11] Mr. Mukund Chougale, Kiran Khairnar, Kajal Bhoi, Rajdeep Magar and Sachin Ingale” Use of Bottom Ash as Road Construction Material: Geotechnical Perspective” International Research Journal of Engineering and Technology (IRJET) June 2019. [12] Dr. Ravi Kumar Sharma and Chayan Gupta” Influence of Waste Materials on Geotechnical Characteristics of Expansive Soil” International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 2 Issue 10, October – 2013. [13] Manoj Sharma, Dr. Ashutosh S. Trivedi and Rohit Sahu” A Review on Various Methods of Road Construction Using Waste Materials” International Journal of Civil Engineering Research. ISSN 2278-3652 Volume 7, Number 2 (2016), pp. 125-133. [14] Mihir Vora1, Divesh Shah, Abhishek Mehta and Eric Mehta” Geotechnical Behaviour of soil using Waste Plastics” International Advanced Research Journal in Science, Engineering and Technology Conference on Advances in Civil Engineering 2018(CACE-2018). [15] Aigbodion, V. S., Hassan, S. B., Ause, T. and Nyior, G.B, \"Potential Utilization of Solid Waste (Bagasse Ash)\", Journal of Minerals & Materials Characterization & Engineering, Vol. 9 (1),pp 67-77. [16] Alhassan, M. \"Potentials of Rice Husk Ash for Soil Stabilization\", A.U. J.T., Vol. 11(4), pp.246-250. [17] Al-Mukhtar, M., Lasledj, A. and Alcover, J. F. \"Behavior and Mineralogy Changes in LimeTreated Expansive Soil at 20°C\", Applied Clay Science, Vol. 50 (2). pp.191-198. [18] Altun, S. and Goktepe. A.B. \"Effects of Freezing and Thawing Processes on the Mechanical Behavior of Silty Soils Stabilized with Fly Ash\". Advances in Transportation Geotechnics, Taylor & Francis Group, London, UK,pp.635-641. [19] ASTM C 618, \"Standard Specification for Coal Fly Ash And Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete, ASTM Standards, pp.310- 313. [20] Nagarajan. “Experimental Study on Partial Replacement of Cement with Coconut Shell Ash in Concrete.”, V. K., et al. 2014 International Journal. [21] Amu, O.O., Ogunniyi, S.A., Aladeji, O.O., 2011. “ Properties of Lateritic Soils Stabilized with Sugarcane Straw Ash”. American Journal of Scientific and Industrial Research, Volume 2(2), pp. 323–331 [22] Aparna, R., 2014. Soil Stabilization using Rice Husk Ash and Cement. International Journal of Civil Engineering Research, Volume 5(1), pp. 49–54 [20] ASTM C618-12a, 2014. Standard Specification for Fly Ash and Raw and Calcined Natural Pozzolan for Use in Concrete. ASTM International. [23] Barasa, P.K., Too, D., Kiptanui J., Mulei, S.M., 2015. Stabilization of Expansive Clay using Lime and Sugarcane Bagasse Ash. International Journal of Science and Research (IJSR), Volume 4(4), pp. 2112–2117 [24] Basha, E.A., Hashim, R., Mahmud, H.B., Muntohar, A.S., 2005, Stabilization of Residual Soils with Rice Husk Ash and Cement. Construction and Building Materials, Volume 19(6), pp 448–453 [25] Chhachhia, A., Mital, A., 2015. Review on Improvement of Clayey Soil Stabilized with Bagasse Ash. International Journal of Research Review in Engineering Science and Technology (IJRREST), Volume 4(1), pp. 238–241 [26] Chittaranjan, M., Vijay, M., Keerthi, D., 2011. Agricultural Wastes as Soil Stabilizers. International Journal of Earth Sciences and Engineering, Volume 04(06), pp. 50–51 [27] Chmeisse, C., 1992. Soil Stabilization using Some Pozzolanic Industrial and Agricultural Products. PhD Dissertation, Department of Civil and Mining Engineering, University of Wollongong. Available Online at http://ro.uow.edu.au/theses/1268, Accessed March 13, 2016 [28] Ekeocha, N.E., Agwuncha, F.N., 2014. Evaluation of Palm Kernel Shells for Use as Stabilizing Agents of Lateritic Soils. Asian Transactions on Basic and Applied Sciences (ATBAS ISSN:2221-4291), Volume 4 [29] Oriola, F., Moses, G., 2010. Groundnut Shell Ash Stabilization of Black Cotton Soil. Electronic Journal of Geotechnical Engineering, Volume15(1), pp. 415–428 [30] Rahman, Z.A., Ashari, H.H., Sahibin, A.R., Tukimat, L., Razi, I.W.M., 2014. Effect of Rice Husk Ash Addition on Geotechnical Characteristics of Treated Residual Soil. American-Eurasian Journal of Agricultural and Environmental Science, Volume 14(12), pp. 1368–1377 [31] Roy. A., 2014. Soil Stabilization using Rice Husk Ash and Cement. International Journal of Civil Engineering Research, Volume 5(1), pp. 49–54 [32] Saleh, S., Srividhya, S., 2015. Stabilization of Weak Soils using Locust Bean Waste Ash (LBWA). International Journal of Research Review in Engineering, Science and Technology (IJRESTs), Volume 1(3), pp. 1–6. [33] Zahra, A., Behzad, K., Armin, R., 2015. A Study using a Variety of Waste Materials as Additives in Soil Stabilization. International Journal of Scientific and Engineering Research, Volume 6(6), pp. 317–322

Copyright

Copyright © 2024 G. Pravalika, K. Koushik Reddy, P. Sanjeev, S. Saketh, Mrs. G. Kalyani . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60218

Publish Date : 2024-04-12

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online